Since COVID arrived three years ago, it has notably damaged the global economy. It caused a supply chain crisis and cost increases,and Varex was forced to face the same challenges as well. Varex management responded by adjusting strategy, promoting global value chain for Varex units, and fostering a local-for-global and global-for-local mindset.

The Varex Wuxi plant in China collaborated closely with the SLC Engineering and Purchasing teams on new vendor development and supply chain optimization to achieve cost effectiveness and on-time delivery. Meanwhile, the management team at the Wuxi plant focused on servicing the Medical Sources solution line in particular, making processes faster and more efficient.

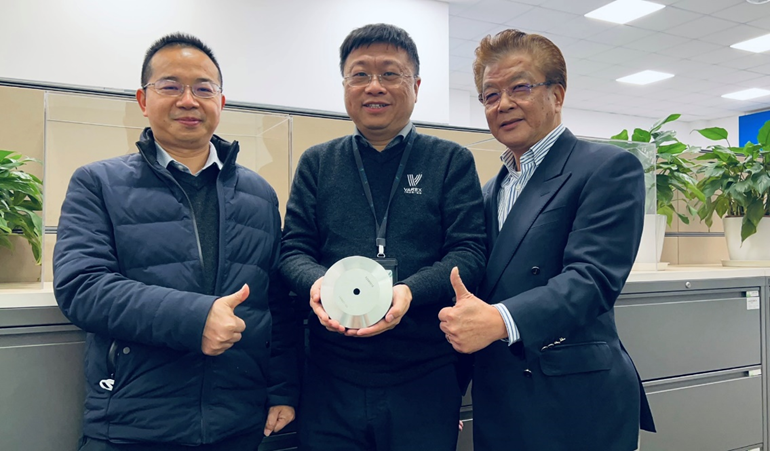

2022 was a year of collaborative achievement, marked by big progress on projects related to inserts of Sources products through joint efforts of SLC lead Jason Davies and the Wuxi Sources team lead Hoyt Shan. Below is an overview of two accomplishments of this global collaboration.

Goal:Promote technology development and innovation to reduce risks of the supply chain.

Challenge: Targets installed in insert manufacturing were stalled until samples were delivered . It had been a difficult year due to material shortages, delivery problems, and a factory shut down.

Solution: Wuxi developed a new vendor, KENI that supplies targets -critical parts with high technical requirements, which also have barriers to manufacturing because of raw materials and process complexities. Prototypes were made successfully under close collaboration between the Varex team and KENI and CMT Rare Metal Advanced Materials (Hunan)Co., Ltd. located in Hunan, China.

This is a Win-Win for both Varex and the Chinese industry. Varex gets a stable supply chain and production capacity that won’t be limited by a single source vendor. And it’s a technical breakthrough and industry development for the Chinese supplier.

本篇报道来自美国万睿视公司网站

参考译文:

全球本地供应商在无锡的合作

自从三年前新冠疫情爆发以来,它对全球经济造成了明显的损害。这导致了供应链危机和成本增加,万睿视(Varex)也被迫面临同样的挑战。万睿视管理层应对的办法是调整战略、提升万睿视部门的全球价值链,以及培养“本地为全球和全球为本地”的观念。

万睿视在中国的无锡工厂与SLC工程和采购团队在开发新供应商和优化供应链方面密切合作,以实现成本效益和准时交货。同时,无锡工厂的管理团队专注于为医疗货源解决方案行业提供服务,使流程更快、更高效。

2022年是合作取得成就的一年,通过SLC主管Jason Davies和无锡货源供应团队主管Hoyt Shan的共同努力,货源供应团队产品相关部件的项目取得了巨大进展。以下概述了这一全球合作的两项成就。

目标:

促进技术开发和创新,降低供应链风险。

挑战:

在交付样品之前,插入件制造中安装的靶材被搁置。由于材料短缺、交货问题和工厂停工等原因,今年是十分艰难的一年。

解决方案:

无锡工厂开发了一家新的供应商,即KENI公司,该供应商提供靶材——具有高技术要求的关键零部件,由于原材料和工艺复杂性,在制造这些零部件时也存在障碍。在万睿视团队与KENI和位于中国湖南的中钨高新稀有金属新材料(湖南)有限公司的密切合作下,成功制作了原型。

这次合作是万睿视和中国企业的一次双赢。万睿视拥有了稳定的供应链和生产能力,将不会受到单一供应商的限制。这也是中国供应商的一次技术突破和行业发展。

Copyrights©2022 中钨稀有金属新材料(湖南)有限公司 地址:湖南省长沙市望城区腾飞路二段99号 营业执照查阅 湘ICP备2022008742号-1 网站地图

技术支持:竞网智赢