A variety of products of the company have been awarded provincial and ministerial awards and awards from the industry associations. We have obtained 46 authorized patents, including 25 invention patents and 21 utility model patents.

Award-winning Products

In 1988, the molybdenum alloy mandrel was awarded the National Quality Award "Silver Award".

In 2011, the tantalum powder for metallurgical purposes was awarded the "Technical Standard Excellence Award" issued by the National Nonferrous Metal Standardization Technical Committee.

Award-winning Projects

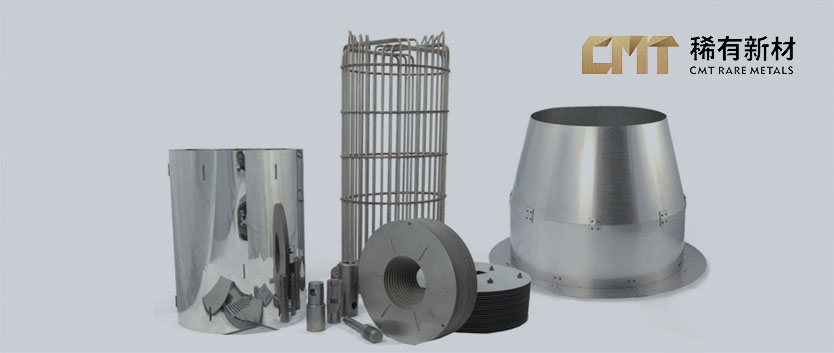

In 2013, the natural science provincial and municipal joint fund project "Research on Forming Mechanism of Tungsten and Molybdenum Materials in High Temperature Heat Zone of Single Crystal Growth Furnace" was successfully completed, and the project achievement "Key

Preparation Technology and Industrialization of Tungsten and Molybdenum High temperature Heat Zone System of Large-size Sapphire Single Crystal Furnace" was awarded the second prize of Science and Technology Award of China Nonferrous Metals Industry in 2014.

In 2021, the sub project of the national key R & D project "Preparation Technology of Large-size High-purity Rare Metal Products", i.e., "Research on Microstructure Evolution Law and Comprehensive Performance Control Mechanism of High-purity Rare Metal Materials" was completed.

In 2022, the sub project of the national key R & D project "Technology and Equipment for Efficient Recovery and Clean Extraction of Refractory Metal Wastes", i.e,, “Research on Rapid Identification and Classification Methods of Refractory Metal Multivariate Complex Wastes “(December 2018 ~ December 2022) will be completed.

Other Innovative Activities

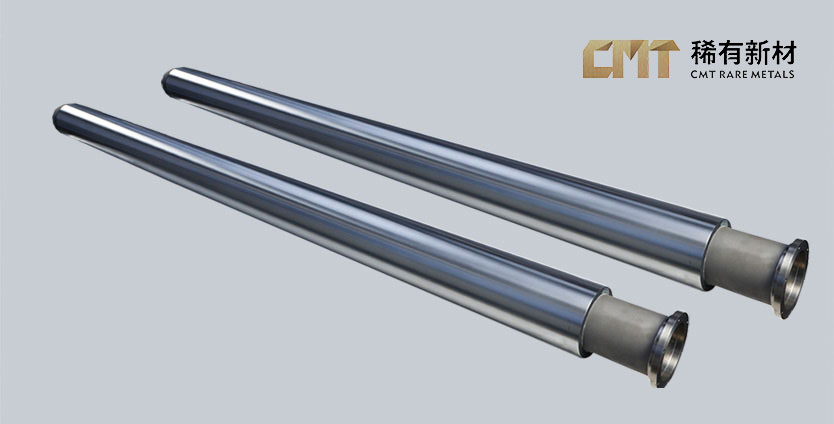

The first tungsten based heavy alloy in China has been successfully developed in cooperation with the new materials research office of Central South Institute of mining and metallurgy, which has been successfully applied in various military aircrafts, nuclear submarines and missiles. At the beginning of 1962, the Ministry of Metallurgy assigned the research task of tungsten based heavy alloy, requiring that the specific gravity (density) of the alloy should not be less than 17.5 g / cm3, tensile strength not less than 75 kg / mm2, i.e. 750 MPa, and that the material can be used under electromagnetic field conditions, which determines that the tungsten content of the alloy should be 93%, The binder metals used shall be Cu and Ni. The task undertaking units were the new material research office of Central South Institute of Mining and Metallurgy and Zhuzhou Cemented Carbide Works.Through independent research and development, molybdenum tube targets for flat panel display have been developed. G6 and G8.5 molybdenum tube targets developed in 2020 have been recognized by major domestic panel manufacturers. This kind of products is a new import substitute product, which is the first in China.